12/26/2023

Health Diary Editorial

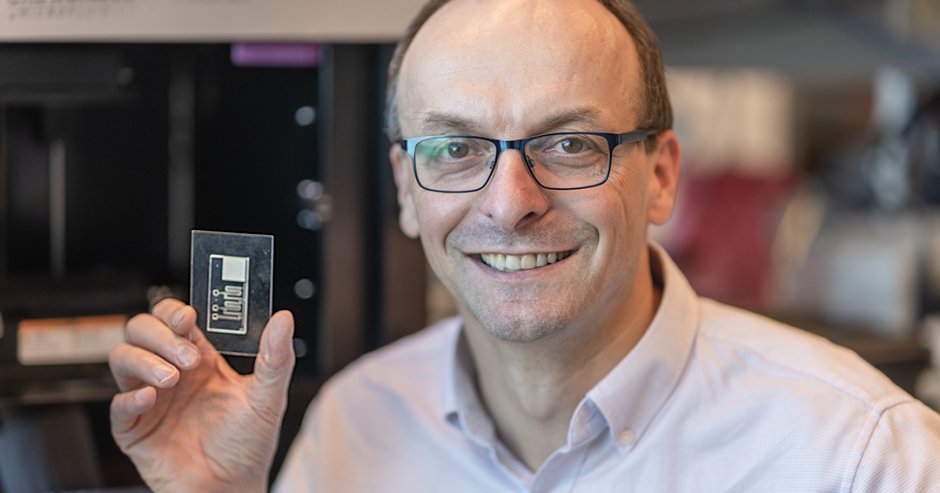

The biochip is simple and low-cost, making on-site diagnosis possible.

[Imagem: McGill University]

Exams inside offices

In a breakthrough in medical diagnostic technology, researchers have invented a “lab-on-a-chip” – also known as biochips or microlabs – that can be manufactured by a 3D printer in just 30 minutes.

This chip could make tests and scans performed directly in a doctor's office more widely available.

Vahid Karamzadeh and his colleagues at McGill University (Canada) have developed hair chips that function as miniature laboratories. Unlike other microfluidic processors, these chips are disposable and do not require an external power supply – a simple strip of paper is sufficient. It works through capillary action, the same phenomenon by which a liquid spilled on a kitchen counter automatically spreads onto the paper towel used to clean it up.

“Traditional diagnostics require peripherals, while our diagnostic devices can work without them,” explained Professor David Junker, team coordinator, “Our diagnostics are a bit like a cell phone for traditional desktop computers, which require a separate monitor, keyboard and power supply to function.” . .

Testing at home, the office, or at the pharmacy has become critical during the COVID-19 pandemic. But rapid tests are limited in availability and can only pass a liquid through the strip, meaning most diagnoses are still made in specialist laboratories.

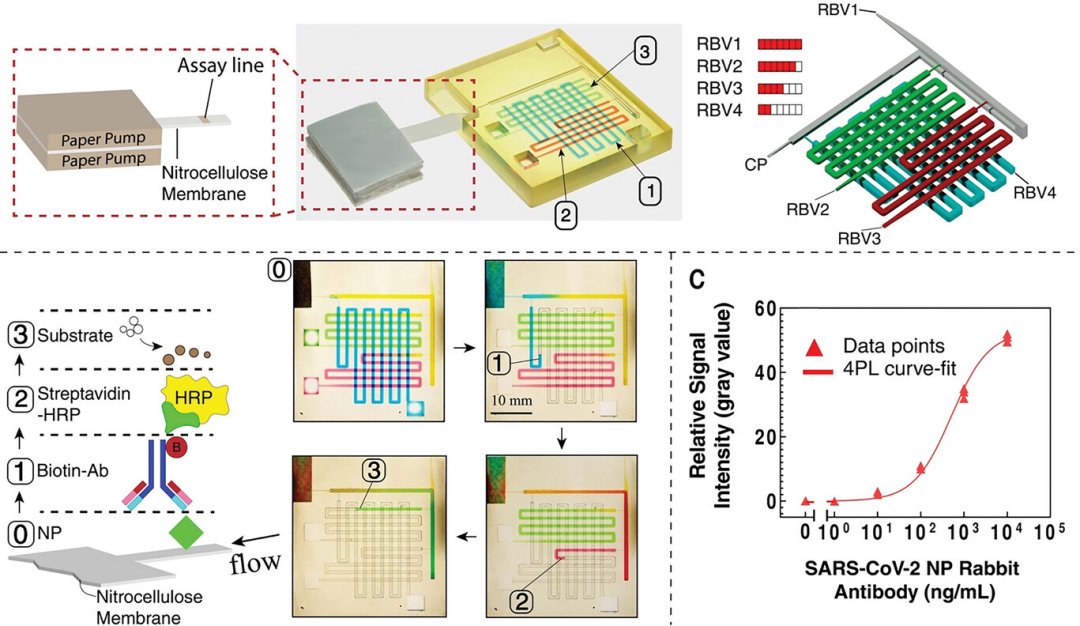

Unlike strips, hair biochips can be 3D printed to perform several different tests, including quantifying coronavirus antibodies.

Each biochip can be 3D printed to perform a specific diagnosis.

[Imagem: Vahid Karamzadeh et al. – 10.1002/adma.202303867]

Explore new possibilities

The team is now working to make their technology even more accessible by adapting it for use with home 3D printers. The ultimate goal is to speed up diagnostics, improve patient care, and usher in a new era of accessible testing.

“This breakthrough has the potential to enable individuals, researchers and industries to explore new possibilities and applications in a more cost-effective and user-friendly way,” Juncker said. “This innovation also has the potential to ultimately empower healthcare professionals with the ability to quickly create customized solutions for specific needs at the point of care.”

condition: Digital fabrication of ready-to-use functional microfluidic systems

Authors: Vahid Karamzadeh, Ahmad Sohrabi Kashani, Molly Sheen, David Junker

Publication: Advanced Materials

Volume: 35, Issue 47, 2303867

doi: 10.1002/adma.202303867

“Writer. Analyst. Avid travel maven. Devoted twitter guru. Unapologetic pop culture expert. General zombie enthusiast.”